RS India : Precision Machining Excellence

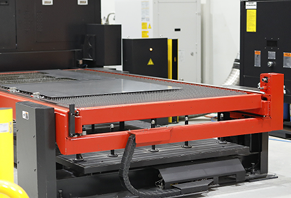

Crafting Excellence with Precision Engineering

Delivering world-class precision machine parts and assemblies, designed to meet the most demanding standards.

Quality Beyond Compare

Adhering to international quality standards to exceed customer expectations.

Your Success, Our Priority

Delivering solutions that are not just precise but also aligned with your unique goals.

Building a Sustainable Future

Integrating eco-friendly practices into precision manufacturing.