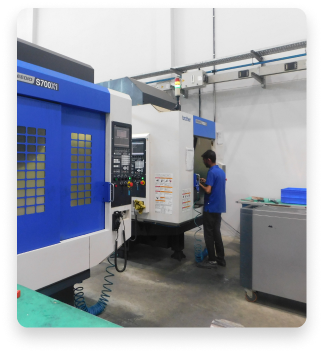

At RS India, we bring your ideas to life with world-class machining capabilities. Our state-of-the-art machine shop, backed by cutting-edge technology, ensures the highest precision and efficiency. Whether it’s simple components or complex geometries, our team of experts works meticulously with a wide range of materials, including steel, aluminum, titanium, plastic, and copper-based alloys.

Our Machining Capabilities:

Ensure high-quality raw materials through precise selection, processing, and refinement to meet industry standards. Optimize efficiency for superior end-product results.

Achieve precise particle size and consistency through advanced milling techniques. Enhance material properties for optimal performance in production.

Shape materials with precision using advanced turning techniques. Achieve smooth finishes and accurate dimensions for superior component quality.

Ensure high precision and efficiency with Swiss-type turning. Ideal for complex, small-diameter components with tight tolerances and superior surface finish

Achieve ultra-fine finishes and precise dimensions with advanced grinding techniques. Enhance material quality and performance for superior end results.